How To Choose The Right Membrane Filter Plate?

What are Membrane filter plates?

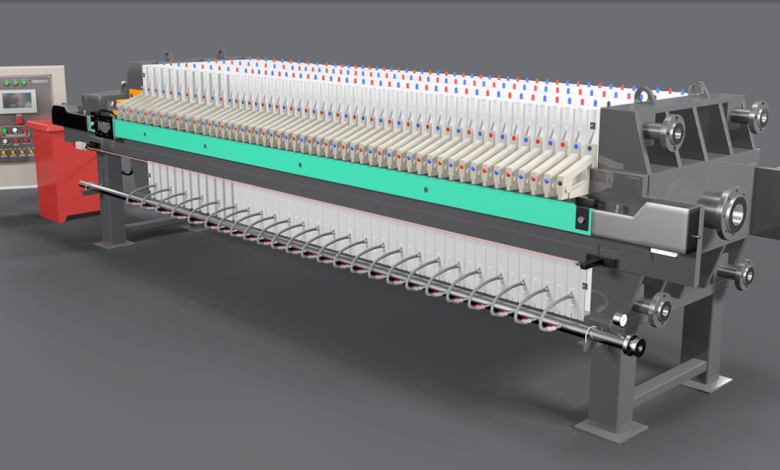

Filter plates, or membrane filter plates, used in filtration applications to separate solid and liquid products from each other. In essence, they plate-like membranes that pores small enough to retain solids while allowing liquids to pass through them. However, it difficult to define exactly what membrane filter plates because their uses vary significantly depending on the application and product being filtered.

An Introduction to Membrane Filter Plates

They say that water life, and indeed, water an essential element for sustaining human life. With 8 glasses of water is recommended every day, it no wonder a large portion of our homes includes some sort of filtration system. We rely on our membranes to help us enjoy clean water, reduce mineral build-up in pipes and ensure. we top-quality equipment. Here’s a quick look at membrane filters. How they work to improve your home’s quality of life: What Are They Made Of? membrane filter plates are made from polypropylene or cellulose acetate depending on what type you purchase.

The Importance of Membrane Filter Plates

Membrane filter plate have a variety of uses, including filtration, analytical, and chromatographic processes. A porous membrane forms one side of the plate and filtrate drains through it to exit via a pipe on the opposite side. Because of their high efficiency, ease of use, relatively low cost and speed in which they operate (typically 300 times faster than conventional filters), they used worldwide in a wide range of industries, including water treatment plants as well as chemical manufacturing facilities. At Filter Manufacturers In India, we manufacture membranes for various industrial applications based on customer specifications. This allows us to provide cost-effective products tailored to suit each customer’s needs.

Types of Filter Media

There are many different kinds of Membrane filter plate and each used for a different purpose. Here’s a brief rundown of some of them: Filtration often done as part of an assembly line in which effluent must flow through several filters; one filter not interfere with another or else you may end up with contaminated products. This accomplished by using multiple types of media, for example, as well as increased surface area. Common filter arrangements include stacks (multiple layers of filters) and spiral configurations.

Filter manufacturers in India use ceramic materials to create filters that provide micron-level filtration but also don’t impact fluid dynamics. Ceramic membranes can handle temperatures from very cold to extremely hot, making them ideal for food processing applications. Filters made from special composite metals called metal-organic frameworks can filter out large molecules while allowing smaller molecules to pass through—perfect for applications such as purifying water without contaminating it with fluoride. Charcoal sometimes combined with other materials to create composite filters designed specifically for given applications or tasks—charcoal alone isn’t enough to purify everything!

Advantages of Washing Media Filter

When you choose The Filter Manufacturers In India, you get access to a team of filter plate experts who truly know their business. You access to top-quality Membrane filter plate and parts, as well as expertise and experience that unmatched in its class. Filter Manufacturers In India keeps your project on schedule with rigorous quality control throughout each stage of fabrication. We use cutting-edge technology to manufacture our filters faster than anyone else, so your filter completed on time every time. And because we specialize exclusively in filter plate manufacturing. we always produce high-quality filters for every application at a price that make your head spin! To learn more about what Filter Press Manufacturers In India do for you contact us today!

Our Advantage Over Other Manufacturers

Membrane filter plate manufacture a complex process that requires multiple steps and numerous processes to finish. Furthermore, ensuring that your filter plate fulfills all of its requirements as per industry standards is essential for any filter manufacturer to succeed in today’s competitive market. With our team having more than 60 years of experience, we have worked in almost every membrane manufacturing process and understand exactly what it takes to meet all requirements laid out by industry regulations. Our experienced team then utilizes their technical knowledge of each process and completes the production on time with consistently high-quality filters.

Know about franchise business